s a device that converts energy into mechanical motion. In aviation, actuators move flight control surfaces, landing gear, engine components, and various other systems critical to an aircraft’s operation. These components translate the commands from the pilot or automated flight systems into physical movements, allowing for precise control and manoeuvrability.

Types of Airplane Actuators

Aeroplane actuators come in various forms, each designed to fulfil specific functions within an aircraft. Some common types include:

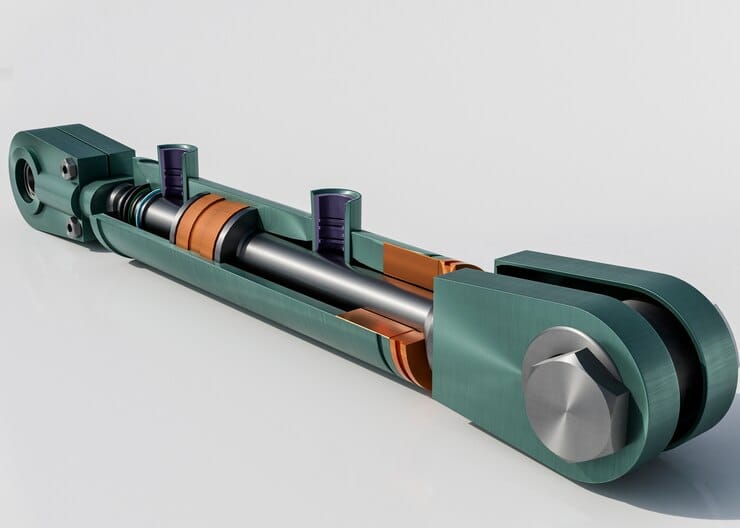

1. Hydraulic Actuators

Hydraulic actuators use pressurised fluid to generate motion. They are commonly found in larger aircraft, providing high force output and precise control. Hydraulic systems are favoured for their reliability and ability to operate under extreme conditions, making them ideal for critical flight control surfaces such as ailerons, elevators, and rudders.

2. Electric Actuators

Electric actuators have gained prominence in modern aviation due to technological advancements and the desire for more efficient and environmentally friendly aircraft systems. These actuators use electric motors to produce mechanical motion, offering benefits such as lower maintenance requirements, reduced weight, and improved energy efficiency. Electric actuators are often employed in secondary flight control surfaces, landing gear mechanisms, and cabin systems.

3. Pneumatic Actuators

Pneumatic actuators use compressed air to drive mechanical motion. While less common in commercial aviation than aerospace hydraulic actuators and electric actuators, pneumatic systems are still used in some aircraft applications, particularly in smaller aircraft and specialised systems such as door operation and braking mechanisms.

Functions of Airplane Actuators

The primary function of aeroplane actuators is to facilitate the movement of flight control surfaces, which are essential for manoeuvring an aircraft in the air. These control surfaces include:

1. Ailerons

Ailerons are hinged control surfaces located on the trailing edge of the wings. They work in pairs, with one aileron moving up while the other moves down, thereby controlling the aircraft’s roll motion.

2. Elevators

Elevators are horizontal control surfaces attached to the trailing edge of the horizontal stabiliser. They deflect upward or downward to control the aircraft’s pitch motion, allowing it to climb, descend, or maintain level flight.

3. Rudders

Rudders are vertical control surfaces mounted on the trailing edge of the vertical stabiliser. They control the aircraft’s yaw motion and help maintain directional stability during flight.

In addition to flight control surfaces, actuators are also employed in other critical aircraft systems, including:

– Landing Gear: Actuators retract and extend the gear during takeoff and landing, ensuring safe ground operations.

– Thrust Reversers: Actuators deploy thrust reversers on jet engines to reverse thrust and assist with braking after landing.

– Spoilers and Flaps: Actuators deploy spoilers and flaps to increase drag and reduce lift during landing, enhancing the aircraft’s stability and control.

Technological Advancements

The field of aeroplane actuators continues to evolve with advancements in materials, electronics, and control systems. One notable trend is the integration of fly-by-wire technology, where electronic signals replace traditional mechanical linkages between the flight controls and actuators. Fly-by-wire systems offer greater flexibility, redundancy, and control precision, enhancing overall safety and efficiency.

Many research and development efforts have gone into improving actuator performance, reliability, and durability while reducing weight and energy consumption. Advancements in aircraft parts manufacturers‘ techniques and materials, such as carbon fibre composites and high-strength alloys, enable the design of lighter and more robust actuators, which contributes to fuel efficiency and environmental sustainability.

Conclusion

Aeroplane actuators play a fundamental role in global aviation by enabling precise control and manoeuvrability. Whether a small general aviation aircraft or a sophisticated commercial airliner, actuators are indispensable components that ensure modern aeroplanes’ safe and efficient operation. As technology advances, the future of aeroplane actuators holds exciting possibilities, promising even greater safety, performance, and innovation in aviation.