Dust series structures play a vital position in maintaining easy and safe working environments throughout numerous industries. Among the additives of these structures, high-flow filters have emerged as an critical solution for reinforcing efficiency and effectiveness. This visitor post explores the numerous benefits of excessive-float filters, their applications in distinct industries, and steering on choosing the proper filters for your dust series desires.

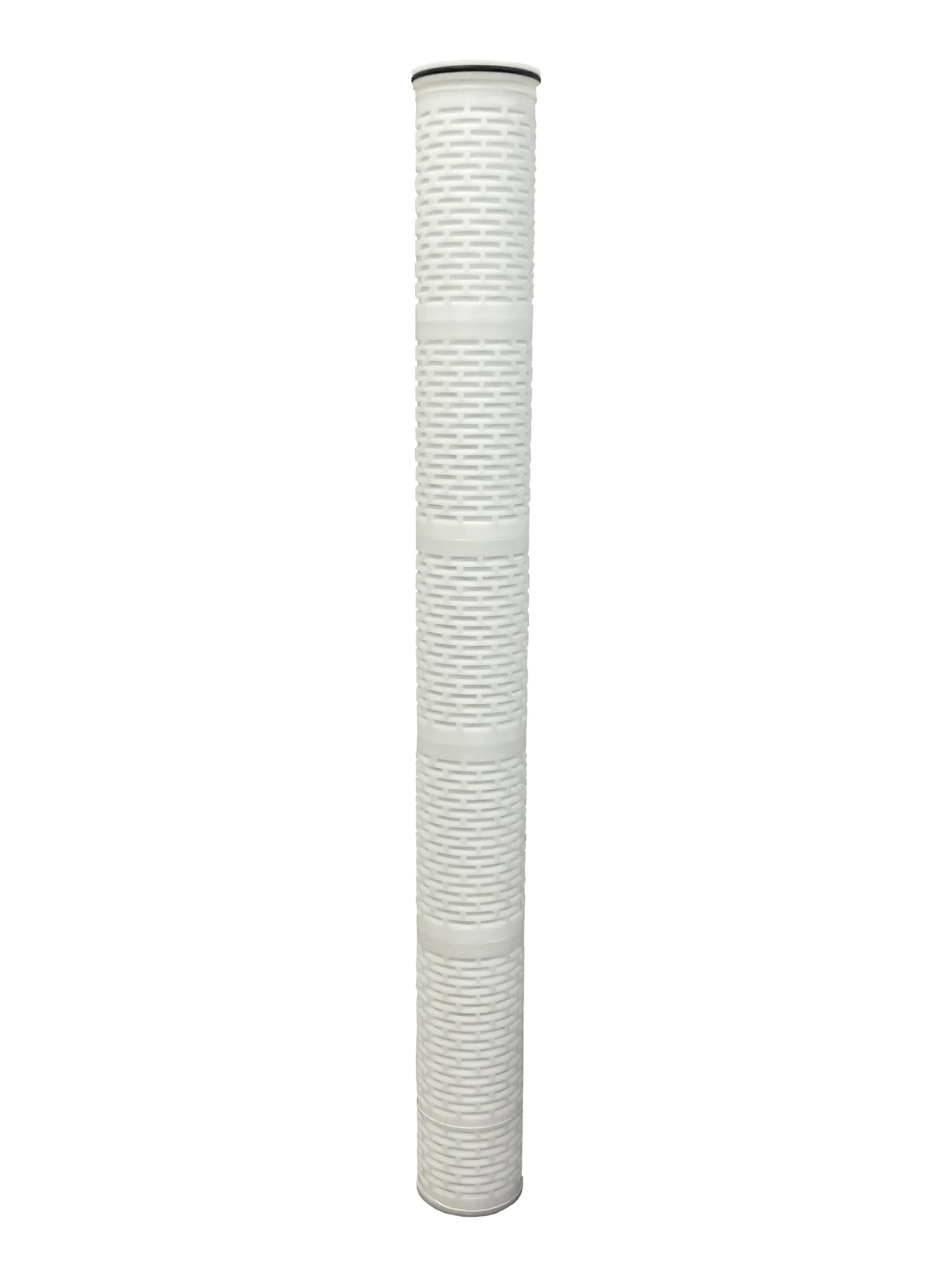

Understanding High-Flow Filters

High-flow filters are designed to handle elevated volumes of air and particulate matter with out compromising filtration performance. Unlike widespread filters, which can also conflict to maintain airflow below excessive dirt masses, high-flow filters utilize superior media era to facilitate superior airflow and seize best particles. This functionality allows industries to optimize their dust collection structures, lessen electricity intake, and enhance normal operational efficiency. High-drift filters are important for centers producing considerable dust, smoke, or particulate depend, supplying a dependable answer for effective air first-class control.

Enhanced Filtration Efficiency

One of the primary blessings of high-waft filters is their improved filtration efficiency. These filters utilize sophisticated media that maximize the surface place for capturing dust particles whilst minimizing resistance to airflow. As a result, excessive-drift filters can efficiently lure each coarse and first-class debris, ensuring cleanser air is returned to the environment. The increased dirt-conserving ability of these filters way they could operate longer before needing renovation or substitute, decreasing operational expenses and downtime. Enhanced filtration efficiency now not handiest improves air high-quality however also contributes to a safer place of job through decreasing the chance of respiratory troubles and other health hazards related to airborne contaminants.

Reduced Pressure Drop

High-float filters are designed to reduce stress drop, a important factor inside the overall performance of dust collection structures. A decrease pressure drop approach that much less power is needed to push air thru the filter, ensuing in lower operational charges and strength intake. This is mainly beneficial for centers with huge dust collection systems that require consistent airflow to keep performance. By using excessive-waft filters, businesses can gain most desirable airflow fees while preserving filtration effectiveness, main to advanced gadget performance and reduced strain on device. Consequently, minimizing pressure drop no longer best enhances performance however additionally extends the lifespan of dirt collection structures, offering long-term cost savings.

Cost-Effective Solution

Implementing high-drift filters in dirt series structures can result in widespread price financial savings over time. The extended lifespan of those filters reduces the frequency of replacements, decreasing the overall price of filter out preservation. Additionally, excessive-flow filters frequently require less power to function due to their lower stress drop, contributing to lower application bills. In many instances, the preliminary investment in excessive-flow clear out generation can be quickly offset with the aid of the financial savings finished through better efficiency and decreased preservation prices. Moreover, the advanced air great due to excessive-waft filters can cause a healthier paintings environment, decreasing capacity healthcare costs associated with dust exposure and enhancing employee productivity.

Versatile Applications

High-glide filters are applied throughout diverse industries, making them a flexible desire for dirt series systems. In production, high-float filters efficiently capture dust generated at some stage in machining and assembly methods, retaining smooth running situations and lowering the hazard of injuries. The woodworking industry benefits from high-flow filters by successfully amassing sawdust and wooden chips, stopping fire dangers and selling cleanser air. Additionally, in industries which includes meals processing, prescribed drugs, and creation, excessive-glide filters play a critical role in ensuring compliance with health and protection rules through efficaciously doing away with airborne contaminants. Their adaptability makes excessive-drift filters an invaluable asset in any dirt series machine.

Selecting the Right High-Flow Filter

Choosing the proper excessive-drift filter on your dust series machine is vital for attaining premiere performance. Start by means of assessing the specific kinds of dirt and debris generated for your facility, as exclusive applications may additionally require various levels of filtration efficiency. Consider the filter’s Minimum Efficiency Reporting Value (MERV) rating, which suggests its ability to capture debris of various sizes. Higher MERV-rated filters are appropriate for programs that generate high-quality dirt, at the same time as decrease-rated filters may also suffice for coarser debris.

Additionally, examine the airflow necessities of your dust collection device to make sure the selected filter out can handle the favored quantity with out huge pressure drops. Consulting with filtration professionals can offer precious insights into deciding on the most appropriate high-waft clear out, ensuring top of the line performance and performance.

Innovations in High-Flow Filter Technology

The subject of excessive-go with the flow filter out era is continuously evolving, with improvements geared toward improving performance and sustainability. Recent advancements include the improvement of nanofiber filter media, which enhances filtration efficiency at the same time as maintaining low strain drops. These superior materials allow for finer particle capture without substantially impacting airflow, making them ideal for high-go with the flow packages.

Furthermore, smart filter tracking systems have become increasingly more famous, enabling customers to song filter overall performance in actual-time. These structures provide treasured statistics on strain drop and dust loading, making an allowance for proactive upkeep selections and reducing operational downtime. Such innovations are reworking dirt series practices, making them more efficient and powerful in retaining easy air exceptional.

The Impact on Workplace Safety

Maintaining easy air in industrial environments is vital for place of job safety and worker health. Dust and particulate rely can pose severe health risks, which includes respiratory troubles and hypersensitive reactions. By enforcing high-flow filters in dust series systems, businesses can considerably lessen airborne contaminants, developing a more healthy paintings environment for employees.

Additionally, powerful dust manipulate minimizes the chance of injuries, which include slips and falls, that could arise while dirt accumulates on surfaces. In addition to enhancing worker nicely-being, maintaining easy air high-quality can beautify productiveness, as workers are less probable to enjoy fatigue or health-associated issues. Investing in excessive-go with the flow dirt collector filters is, therefore, a proactive step towards promoting administrative center safety and productivity.

Conclusion

High-glide filters are a important element of present day dirt series structures, providing numerous blessings that decorate efficiency, lessen fees, and enhance air fine. With their potential to capture high-quality particles, reduce pressure drops, and perform efficaciously throughout diverse industries, excessive-waft filters are important for retaining clean and safe running environments. By deciding on the bag filter housing and embracing innovations in filtration technology, companies can optimize their dirt series structures and make contributions to a more healthy, more secure workplace.

Investing in high-go with the flow filter answers no longer most effective advantages businesses thru operational efficiency and fee savings but also demonstrates a dedication to employee well-being and environmental responsibility.